GLOBAL INDUSTRY LEADERS EXPERIENCED ASAHI’S AWP™-REVO ECOSYSTEM IN ACTION IN JAPAN

Customers and partners from the global flexographic community gathered at Asahi’s Fuji Plant and Tokyo headquarters to experience the new AWP™-REVO Ecosystem and its impressive print results, marking another milestone on Asahi’s journey toward Solvent ZERO.

Asahi Photoproducts, a pioneer in sustainable flexographic plate development and a subsidiary of the Asahi Kasei Corporation, successfully hosted AWP Days 2025 in Japan. The annual event brought together top executives from leading printing and packaging companies around the world.

The AWP™-REVO Ecosystem Demonstration Took Center Stage

A highlight of AWP Days 2025 was the live demonstration of the AWP™-REVO Ecosystem, Asahi’s latest innovation designed to support a detergent-free, water-based platemaking process. Visitors had the opportunity to see the complete system in action, including the AWP™-REVO plate, the AWP™-REVO-2530AA Plate Processor, and the AWP-LOOP™ Petite water recycling unit.

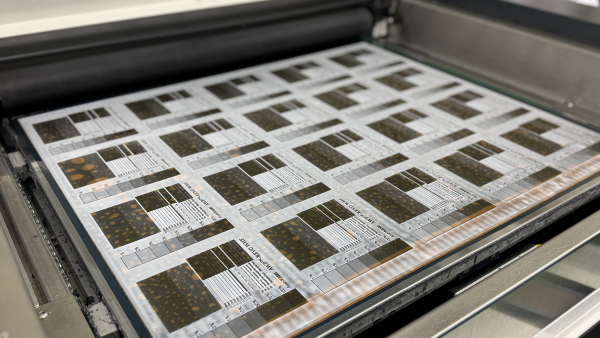

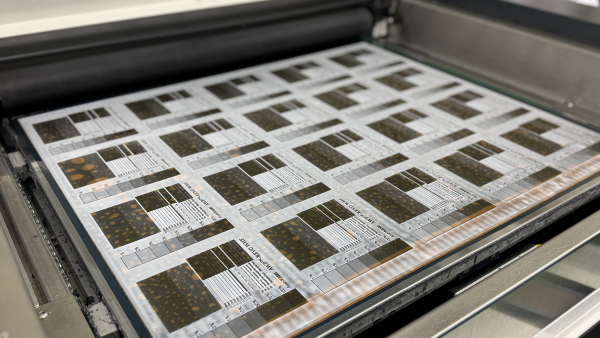

During the factory tour, attendees observed how the solution enables fully water-washable plate processing and delivers exceptional print consistency while minimizing resource consumption. Print samples produced with the AWP™-REVO plates demonstrated remarkable registration accuracy, high solid densities, and reduced downtime thanks to Asahi’s CleanPrint technology.

As Aki Kato, Senior General Manager of Asahi Kasei Photoproducts Division, noted, the engagement and feedback from guests were invaluable: “It was a great pleasure to welcome our valued partners and customers from across the world to Japan. Seeing them experience the AWP™-REVO Ecosystem in action and discuss how it supports their sustainability and productivity goals was truly inspiring. Their feedback confirmed that we are on the right path toward a Solvent ZERO future, combining innovation, collaboration, and environmental responsibility.”

Strengthening the Path Toward Solvent ZERO

AWP Days 2025 once again demonstrated the value of bringing customers and partners together to share insights and witness real-world results. Following the event, Asahi will continue to build on the momentum of the AWP™ plate and AWP™-REVO Ecosystem, expanding its applications for plate technologies. The company remains dedicated to helping customers worldwide achieve higher quality and sustainability standards through close collaboration and continuous innovation.

Print samples produced with the AWP™-REVO plates demonstrated exceptional color accuracy and consistency achieved with Asahi’s CleanPrint technology.

Guests observed the full AWP™-REVO Ecosystem in action during the plant tour, featuring the AWP™-REVO plate, the AWP™-REVO-2530AA Plate Processor, and the AWP-LOOP™ Petite water recycling unit – a complete detergent-free, water-washable flexographic platemaking solution.