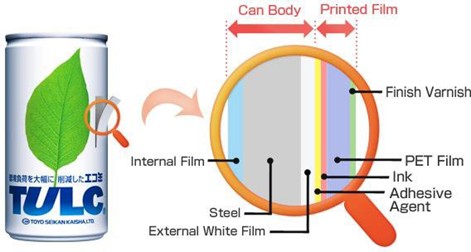

TULC Cans, “Environmentally Friendly Packaging”

TULC cans are packaging products derived from technology developed and invented by Toyo Seikan Co., Ltd., by relying on the general can production process improvement for beverages. The TULC can production was first started in 1991, and up until now, the TULC cans have infiltrated into the Japanese packaging market with the market sharing of twenty percent (20%) or about 7 billion cans and tend to be much increased in the future.

In the first phase, TULC cans had been developed under the principles of the Life Cycle Assessment (LCA) where the use of the natural raw materials in the least quantity but with the maximum advantages, was taken into account, by reducing the emission of carbon dioxide (CO2) from the TULC can production process to be down merely at twenty percent (20%) and reducing the energy consumptions by twenty-six percent (26%) compared to the generally conventional can productions of Draw and Wall Ironing (DWI) type.

The Toyo Ultimate Lightweight Can is a 2-piece can made of Tin Free Steel (TFS) or Aluminum with Polyethylene Terephthalate (PET), both inside and outside.

Spray coating and baking process to stabilize the polymer is different from those of the DWI cans that use coating solution and dried with heat, thus, resulting in the CO2 quantity emitted to the air to be reduced to be lesser than one-third. Therefore, the distinctive feature of TULC cans is remarkable in terms of the light weight, reduction in the energy consumptions and that they can be reused or recycled. At present, Bangkok Can Manufacturing Co., Ltd., is the first company in Thailand to install the machine to produce TULC cans.

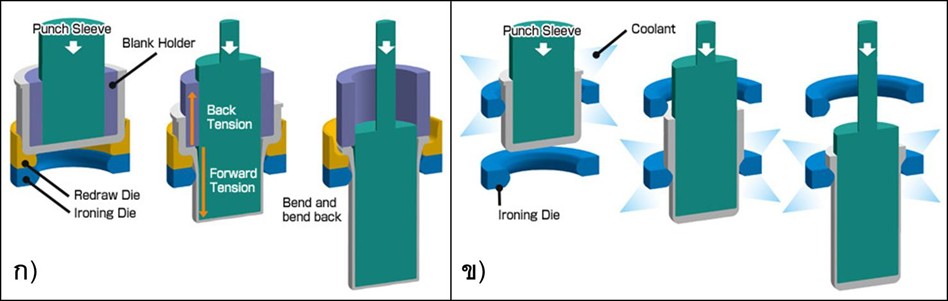

Technology used in the production is a non-water use technology. Therefore, it does not cause any water pollution. The generally conventional DWI canning processes requires a large quantity of water to help reduce the heat during the ironing and washing process, but TULC cans are formed up by Dry Forming, thus, reducing water consumption by up to 9,000 cubic meters/month/production line. Whereon the amount of waste metals or other solid debris occurring after the wastewater treatment in the TULC can production process is reduced to remain at only 120 kg/month/production line while the DWI cans account for about 40 tons of waste/month/production line.

If materials used in the production should be taken into consideration, it could be found that the production technology is still the technology enhancing recycling. The main raw materials used in the TFS production are easier for recycling, including PET films that do not cause any toxic gas in the air when burned because it will be decomposed into CO2 hydrogen and oxygen.

In addition, TULC cans have the property to protect the product contained inside to retain the taste, color and aroma better than DWI cans where the interior surfaces of which are coated with lacquer while TULC cans are covered with strong PET films that do not absorb product odors and flavors.

Source : http://www.toyo-seikan.co.jp

Source : http//www.ajinomoto.co.th/print_new