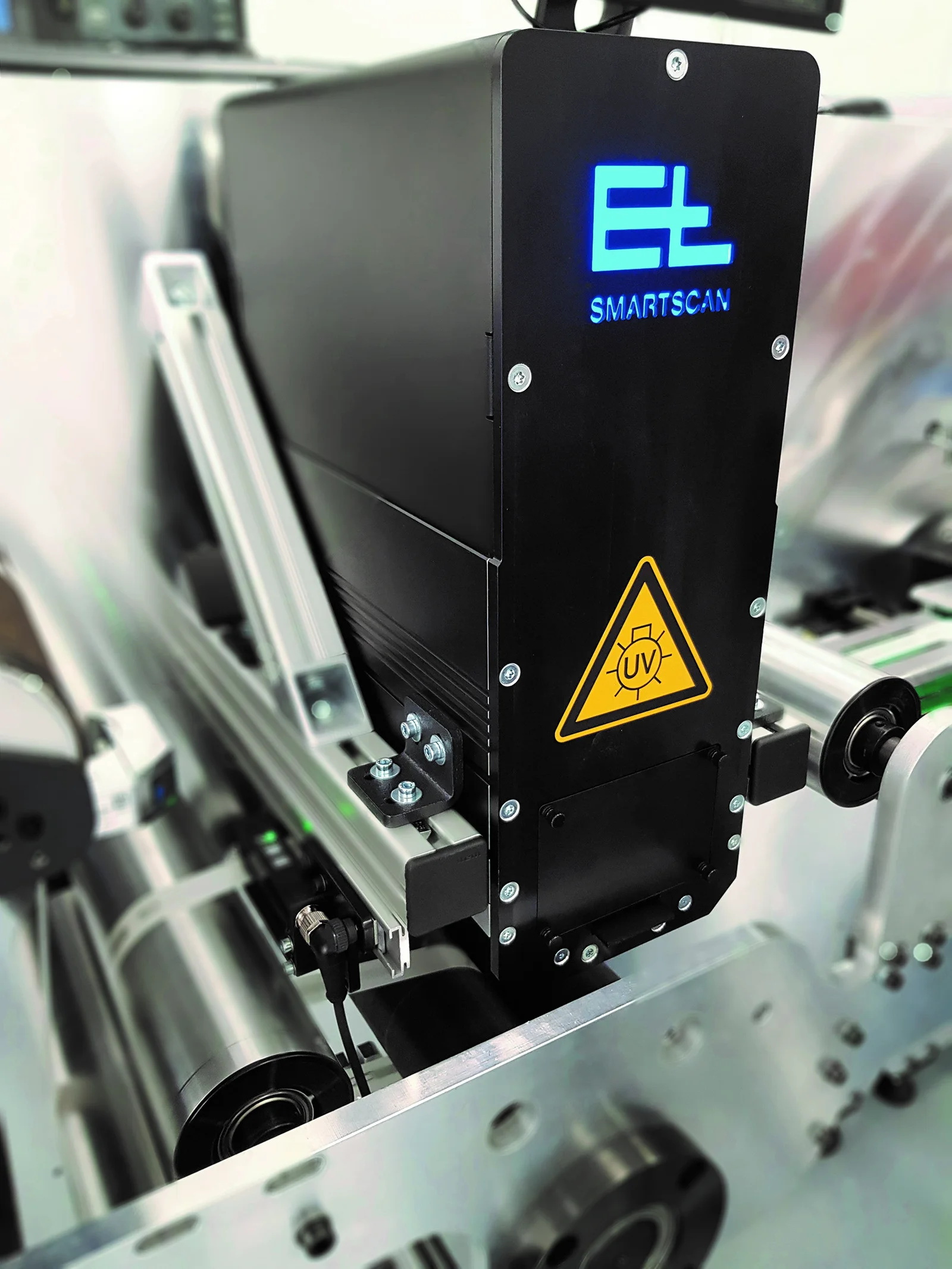

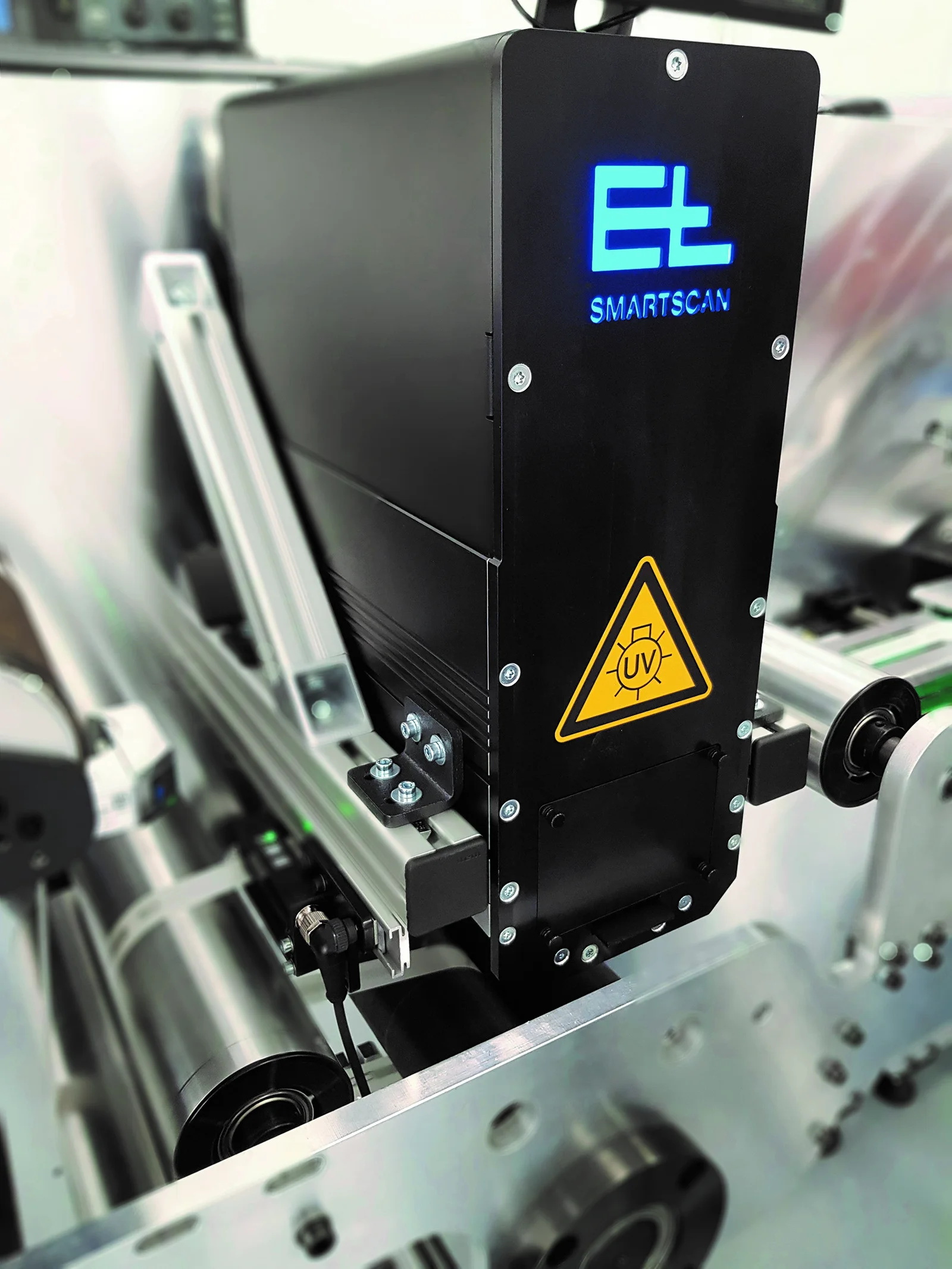

New generation of SMARTSCAN 200% print image inspection

The new generation of SMARTSCAN can be installed in the familiar way on printing machines and rewinders. SMARTSCAN – or the MIS2 model to be more specific – is now faster and more compact, and it has a new design. On the variant with 2K resolution, we have already been able to achieve speeds of up to 600 m/min. But the 4K variant is catching up, and is now reaching speeds of up to 400 m/min. Faster LEDs and an optimized lighting concept deliver even better image quality. The reflection module for displaying reflective, usually metal-coated materials or finishing foils (e.g. gold, silver) is now included as standard. The same applies to the exchangeable background panel, which is advantageous for transparent materials in particular. With this package, users can trust that they are playing it safe in most areas, e.g. for label or packaging printing. The height of the camera units has been significantly reduced but no compromises have been made in terms of the standard functions such as the integrated lighting on the rear panel or the roller guidance. A new installation concept makes integration in the printing machine or the rewinder even easier.

Previously, SMARTSCAN was available with a maximum width of 560 mm (22 inches), but with the latest generation E+L now also offers 660 mm (26 inches) and 760 mm (30 inches). In addition, the software has been optimized and expanded. New defect detection algorithms spot defects with even greater reliability. The same applies to the defect classification system, which assigns defects to categories such as missing label, unremoved matrix, print error, glue joint or flag even more reliably than before. Further defect classes such as hole, barcode or incorrect length are also available. With all these options for capturing defects and errors, comprehensive evaluations can be performed in order to understand and optimize production processes. The tried and tested 200% inspection technology will, of course, continue to be used. Improvements have also been made to the detection of hole defects and to the illumination of fluorescent materials. But special applications, such as the production of labels with integrated RFID antennas, will also benefit from the new features.

Source: https://www.erhardt-leimer.com/us/en/company/news/press/erhardt-leimer-auf-der-drupa-2024.html