K2022: Partnership Excellence that Drives DOMO’s Sustainable Polyamide Solutions

DOMO Chemicals, a leader in polyamide-based engineered material solutions and services, is set to present its entire range of high-performing TECHNYL® solutions to a global audience for the first time at the upcoming K 2022 show in Düsseldorf, Germany Creating and using circular solutions with reduced carbon footprints continues to be a major challenge for the industry.

Recent developments in lightweighting, metal replacement, thermal management and e-mobility reinforce the global need for sustainable and high performing polyamide-based solutions. At K 2022, DOMO will show a range of new solutions designed to meet these growing needs.

The TECHNYL® 4EARTH portfolio continues to expand, and a key highlight at K 2022 will be the launch of two new circular lines in the product family. Designed for cooling applications, the TECHNYL® 4EARTH A1E 218 V30 BK 34NG LP is a sustainable variant of DOMO’s leading coolant resistant grade (TECHNYL® A 218 V30 BK 34NG). For E&E market needs, the TECHNYL® 4EARTH HFFR and flame-retardant polyamides available in gray and white are based on recycled feedstock with reduced CO2 emissions compared to virgin alternatives.

Another major focus for DOMO at K 2022 will be geared towards supporting increased processability in the E&E market. TECHNYL® C 102 NC DF, for example, is a new PA6-based, unfilled solution that provides optimal processability and is aligned with market standard requirements, especially for the production of electric plugs, sockets, switches and connectors.

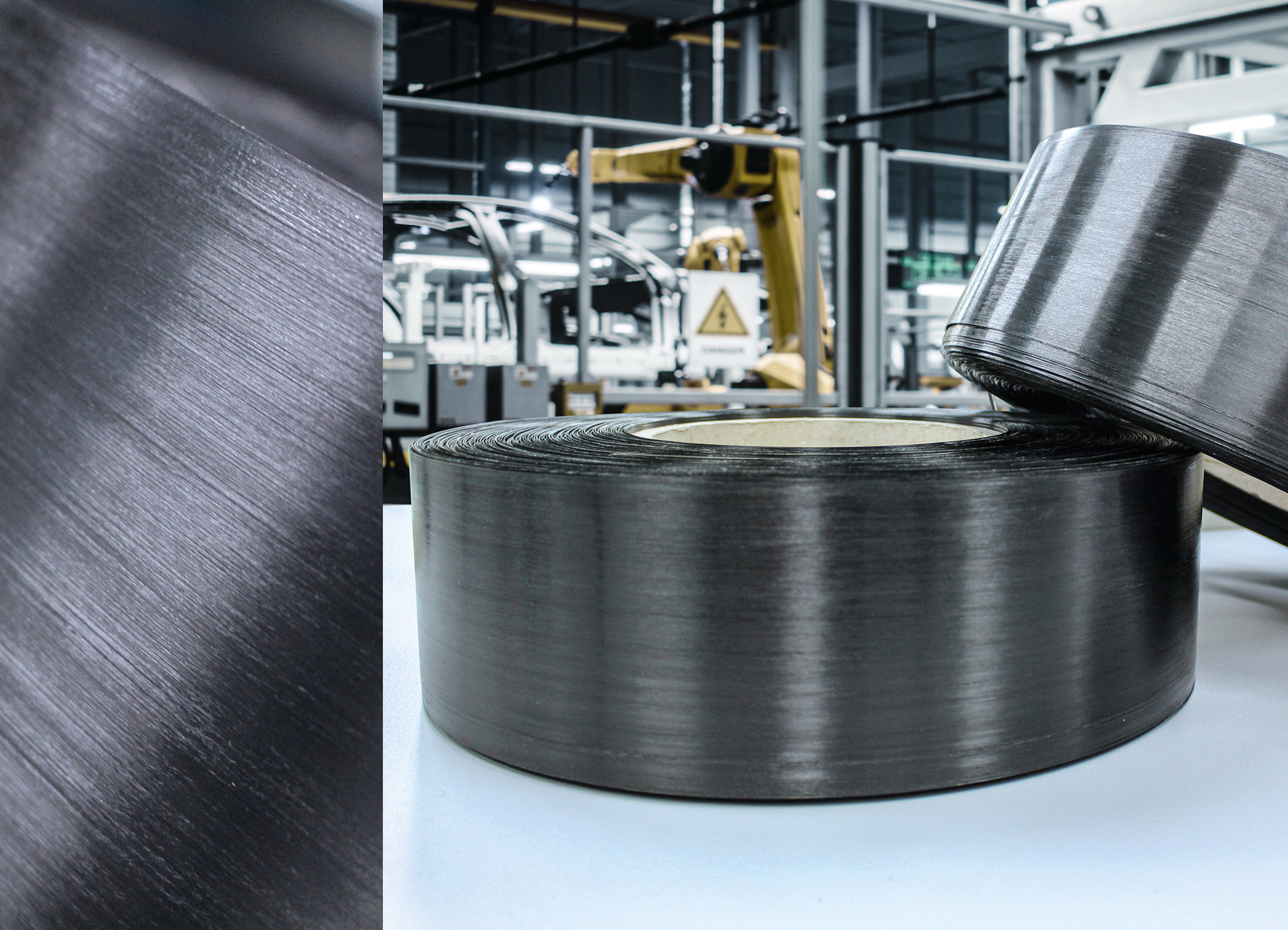

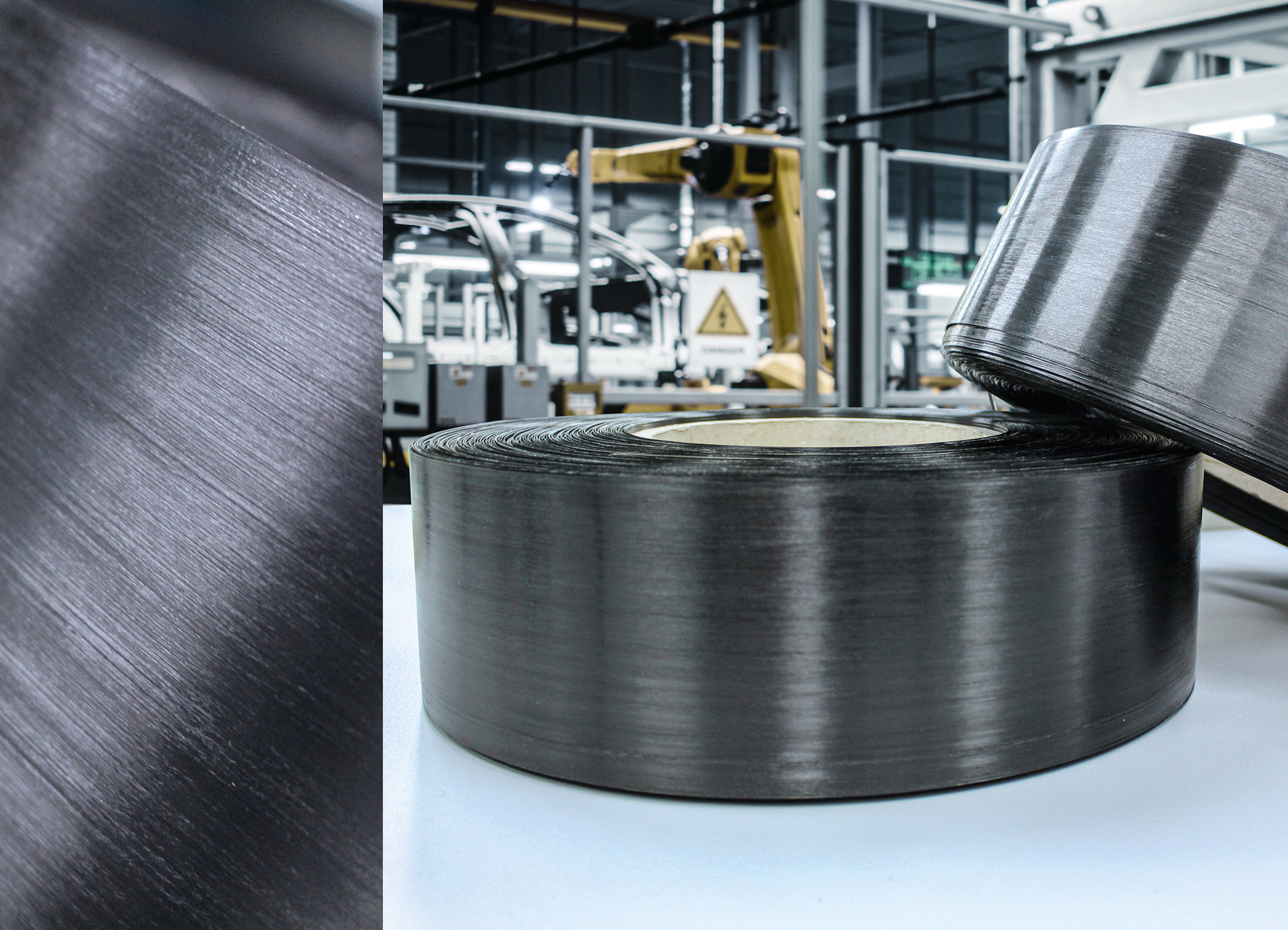

In the domain of e-mobility, new electrically friendly and orange solutions will be presented with improved electrical performance and processability, together with color retention capability beyond aging at 130°C for 1000h. In addition, DOMO will be showcasing its unidirectional UD tapes (composites) with high stiffness and strength for lightweighting solutions under its new brand, TECHNYL® Lite. These tapes will help further enhance plastic applications, specifically for structural parts used in automotive and consumer goods.

Working closely with customers, DOMO recognizes a shift away from pipe, fittings, pumps, valves and other components being made from traditional materials such as brass, steel and other metals. There is an increasing demand for innovation among water management solutions, and this is where TECHNYL® SAFE plays a key role. Visitors at K can expect full insight from DOMO’s experts on how this sustainable product is making strides for higher performing systems that are better protected against corrosion and degradation.

Currently, around 10% of DOMO’s product sales are from circular solutions. The company plans to grow this to 20% by the end of the decade, and to 30% by 2035. The key to this will be the development of Nylon 6 and 66 quality feedstocks for use in high-quality engineering compounds. Here, DOMO is exploring technologies and solutions around depolymerization, nylon dissolving, and new feedstock recycling.