IMD and Dye Penetration technologies add sustainability of the plastics industry.

By Pat Williams Vice President of Rosti Asia

The plastics industry has been under intense scrutiny over the past few years due to its impact on the environment. Plastic waste is one of the biggest environmental challenges we face today, with single-use plastic products such as straws and bags finding their way into our oceans and natural habitats. In recent years, the industry has been looking for ways to reduce its impact on the environment, and two innovative solutions are in-mould decoration (IMD) and dye penetration technologies.

As a leading plastic injection moulding and contract manufacturing company, Rosti has been working to reduce the environmental impact of its injection moulding decoration technologies through innovation and ongoing process improvement. By developing and introducing In Mould Decoration (IMD) and Dye Penetration technology, Rosti is working with clients to mitigate the environmental impact of injection moulding decoration on a range of products across business and consumer categories.

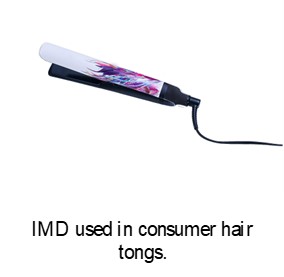

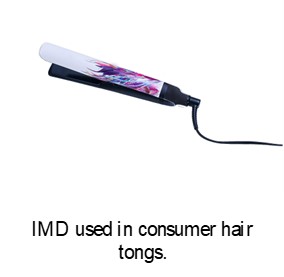

IMD is a process that involves applying a decorative film or label onto a plastic product during the manufacturing process. The process involves placing a pre-printed film or label into the mould and injecting the molten plastic around it. This results in the decoration being integrated directly into the plastic product, which provides a durable and long-lasting finish that is not subject to wear and tear. In one instance, Rosti developed a proprietary IMD process in collaboration with foil supplier Kurz, for haircare products promotional campaign.

The use of IMD has several benefits for the environment. Firstly, the process reduces the amount of waste generated during the production of plastic products. Traditional methods of decoration, such as screen printing or adhesive labels, generate a significant amount of waste material that needs to be disposed of. With IMD, the decorative film or label is applied directly to the product, eliminating the need for excess waste.

Secondly, IMD can help to reduce the environmental impact of plastic products during their use. The durability of the decoration provided by IMD means that the products are less likely to become damaged or worn over time, reducing the need for replacement. This can help to extend the lifespan of products, reducing the number of products that end up in landfill.

Finally, IMD allows for the use of more sustainable materials in the production of plastic products. Traditional printing and labelling methods can be limited in terms of the types of materials they can be used on. However, with IMD, a wider range of materials can be used, including recycled and bio-based plastics. This means that products can be made with a lower environmental impact, without compromising on aesthetics or functionality.

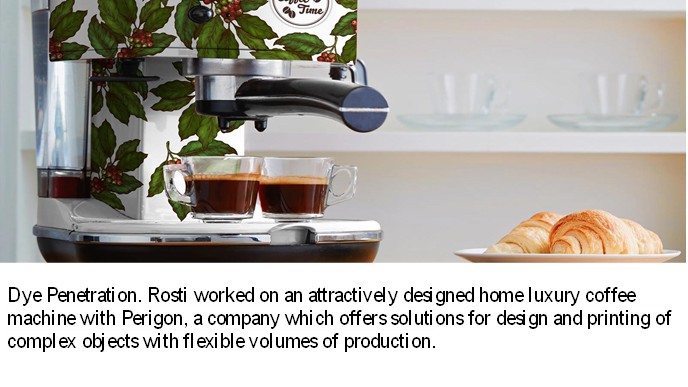

Rosti’s recent application of Dye Penetration technology has enabled the creation of complex shapes, regardless of material and volume, and eliminates the need for painting, making it an environmentally friendly solution. This technology transfers graphics from digital printed film onto products under heat and vacuum, enabling cosmetic artwork with no restrictions on the number of colours or production volume. By eliminating the need for additional processes and reducing waste, this technology significantly reduces the environmental impact of injection moulding decoration.

Dye penetration is a printing process in which ink is converted from solid state to gaseous state under high temperature and negative pressure, so that ink infiltrates into the surface of the material and achieves intermolecular bonding with it to form a specified pattern on the surface of the product. The dye penetrates the plastic, bonding with the molecules and creating a highly durable colour that resists fading, scratching, and other forms of wear and tear. This process enhances the visual appeal of the plastic, making it ideal for a wide range of applications, including automotive components, consumer electronics, and even medical devices.

But how does this process benefit sustainability efforts? Firstly, dye technology reduces the need for frequent replacements due to wear and tear. Plastics that have undergone dye penetration technology last longer, reducing the amount of plastic waste generated. Secondly, the dye used in the process is non-toxic and environmentally friendly, making it a safer alternative to traditional dyes that can harm the environment. Finally, the technology allows for precise colour matching, reducing the need for additional manufacturing steps such as painting or coating. This, in turn, reduces the amount of energy and resources needed to produce the final product, promoting sustainable practices.

The use of new technologies and processes will help to reduce the impact of the plastics industry on the environment. By reducing waste, extending product lifespan, and enabling the use of more sustainable materials, IMD and dye penetration offer more environmentally friendly alternatives to traditional decoration and moulding methods. As the industry continues to search for ways to reduce its environmental impact, these innovations will ensure that consumers can enjoy the benefits of functional and attractive packaging and companies can play their part in sustainability.