Plastics, Rubber & Composites Take the Spotlight: PMT Exhibition Draws Global Attention

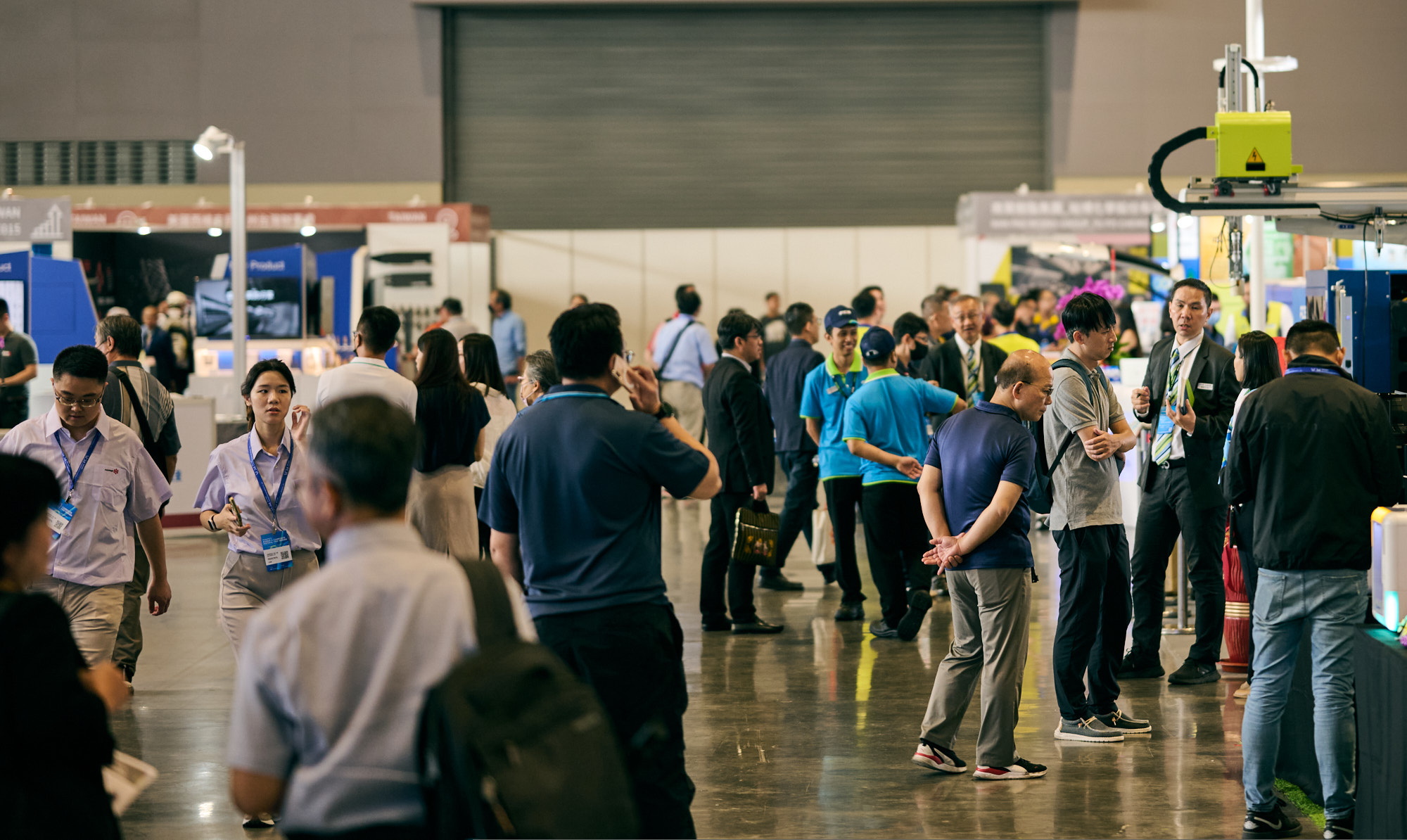

The 2025 Plastics, Rubber & Composite Material Fair Taiwan (PMT) officially opened today (June 4 2025) at the ICC Tainan. Advised by the Bureau of Foreign Trade and organized by Venturap conference & Exhibition Co., Ltd. the show debuts with a fresh curatorial approach and effective matchmaking services, creating a professional international platform for the materials industry. In its inaugural edition, PMT has attracted 110 leading companies from 7 countries, showcasing the full value chain from raw materials and processing machinery to high-value applications and digital manufacturing highlighting both its global potential and industrial significance.

According to 2024 data, Taiwan’s plastics and rubber machinery exports reached USD 640 million, making it the sixth-largest exporter in the world. Major markets include Southeast Asia, Europe, and the Americas. At the same time, composite materials are seeing rapid demand growth in aerospace, automotive, bicycles, and sporting goods. Taiwanese companies are actively investing in material R&D and process optimization, demonstrating strong technical resilience and flexible manufacturing capabilities. With a backbone of agile and customized small-to-medium enterprises, Taiwan’s plastics, rubber, and composite industries must now respond to global pressures of carbon neutrality and supply chain restructuring through international collaboration, innovation, and brand development. The launch of PMT comes at a crucial time to address these needs offering a platform for innovation showcase, global networking, and business matchmaking to boost the industry’s competitiveness.

The opening ceremony was officiated by Deputy Mayor Chao Ching-Hui of Tainan City, who highlighted that PMT provides a vital platform for introducing advanced manufacturing and material R&D into Tainan, while also strengthening its ties with global industrial chains. She emphasized that Southern Taiwan Science Park (STSP) and Shalun Smart Green Energy Science City serve as Tainan’s dual economic engines. Shalun has already welcomed top national research institutions including Academia Sinica’s Southern Campus, NARLabs, and ITRI. Through the exhibition, the city aims to showcase its tech development and promote the emerging Shalun innovation cluster.

The ribbon-cutting ceremony was jointly led by Deputy Mayor Chao, Mr. Huang Ying-Wen, Vice Chairman of the Taiwan Plastics Industry Association, Dr. Kuo-Ting Liao, Chairman of the Taiwan Advanced Material Technology Association, Mr. Huang Tsung-Yu, Chairman of the Taiwan Synthetic Resins & Adhesives Association, and Ms. Joanne Liao, Vice Chair of the Taiwan Biomass & Sustainable Materials Industry Association marking the official launch of this landmark event. This year’s exhibition gathers top-tier companies including Fong Kee International, FCS Group, Chang Chun Plastics, and BASF Taiwan, presenting a wide range of products and solutions from raw materials and composites to smart machinery, efficient processing, and high-value applications demonstrating Taiwan’s comprehensive industry capabilities and its critical role in the global supply chain.

PMT has also captured strong international media interest. Major industrial media outlets such as The Nikkan Kogyo Shimbun (Japan), Interempresas Media (Spain), PLASTECH (Poland), The Korea Industry Daily (Korea), and Asia Pacific Plas & Pack (Thailand) are visiting Taiwan for exclusive coverage underscoring the country’s growing presence on the global materials stage.

In line with digital transformation, PMT features the “EXPO-TECH Smart Exhibition Program,” offering an immersive exhibition experience with five digital highlights: a green energy interaction station, multi-user interactive product tables, 3D holographic projections, exhibition robots, digital survey kiosks, and multilingual guidance systems creating a tech-driven, sustainable, and globally accessible show.

Conference on the Creation of New Integrated Innovation Concept Increases Business Opportunities for Plastic and Rubber Sector

One of the key events, the 2025 PMT SUMMIT – Materials Industry Innovation Forum, also kicked off today. The forum focuses on crucial topics including net-zero carbon, smart manufacturing, advanced material applications, and innovative injection technologies. Featured speakers include Mr. Kuan-Chih Lee, Director General of the Small and Medium Enterprise and Startup Administration (Ministry of Economic Affairs); Mr. Yao-Kuei Hsiao, General Manager of the Plastics Industry Development Center; Mr. Laurent Poisson, Area Sales Manager at France’s PINETTE PEI; Mr. Chun-Chi Lai, General Manager of GEOFOC Material; and Ms. Hsiao-Hui Sun, Manager at NatureWorks LLC. Together, they bring global perspectives and cutting-edge insights to energize Taiwan’s innovation momentum.

The successful debut of PMT marks a new chapter for Taiwan’s materials industry and lays a solid foundation for its position in advanced manufacturing and sustainable innovation on the world stage.

Looking ahead, PMT’s partner event the TMTS 2026 Taiwan International Machine Tool Show will take place on March 25, 2026, at the brand-new Taichung International Exhibition Center. With the theme “AI Empowerment, Smart & Sustainable Manufacturing,” the event will highlight digital and green transformation, connecting smart manufacturing, ecosystem partnerships, and cross-industry integration. Starting from June 4, exhibitor registration is officially open, signaling a united push to accelerate Taiwan’s manufacturing exports to the global market.

Plastics and Rubber Technology Leaders Showcase Their Innovations

GREAT Biomaterials Co., Ltd., has over 70 years of experience in chemical manufacturing through its affiliation with AVATACK by expanding its scope from traditional material development to environmentally friendly materials, which is an aim at solving the environmental crisis caused by plastics pollution. With robust expertise in formulation design and modification technology, GREAT is committed to continuous innovation to develop high-performance, sustainable materials opening the door to a greener future for its clients. In this regard,

Mr. Kevin Chang, Project Manager, stated: We bring more than 70 years of experience from AVATACK, a leading manufacturer of adhesive tapes with a strong focus on environmental preservation. Our product range includes various grades and types of plastic pellets such as Recycled, Biomass, Biodegradable, and Compostable pellets. In addition, we utilize PCR (Post-Consumer Recycled) and PIR (Post-Industrial Recycled) materials to enhance recycling processes, align with global sustainability trends, and reduce carbon emissions. We are continuously committed to complete plastic pellet recycling and optimizing circular systems to minimize the use of virgin plastics. At this year’s PMT event, we put on display to show a series of products made from different types of recycled plastic pellets including various types of adhesive tapes such as Plant-Based Tape, Recycled PP Tape, Recycled PET Tape, and Eco-Friendly Paper Packaging Tape for use in logistics work. We also present recycled plastic packaging products such as rPE Shrink Film and rPE Pallet Wrap, etc.

“Our headquarters and production facilities are located in Taiwan, with sales offices around the globe including one in Thailand to support local industries that wish to integrate our products into their operations.”

Chuan Lih Fa Machinery Works Co., Ltd., (CLF), established for business operations in 1966, has grown from a local factory into a globally recognized brand in plastic injection molding machinery. Starting with small-sized machines, the company has continually advanced through the developments and innovations.

Currently, CLF focuses on R&D, manufacturing, and distribution of a wide range of injection molding machines. It is widely recognized as a leading manufacturer of large-scale, high-precision, and energy-efficient plastic injection machines—designed to optimize factory performance. Mr. Jeff Lin, Sales Engineer, gave his account on this matter: “CLF is a leading Taiwanese manufacturer of automated plastic injection molding machinery. At this event, we are presenting the TPII Series Two Platen Injection Molding Machines, ranging from 500 to 4,000 tons. These machines’ uniquely outstanding features are their speeds, precision, energy efficiency, and environmentally friendly, reductions of carbon emissions and operational costs, thus, making them ideally suitable for producing large automotive parts and being able to customize for multi-color injection molding, adding value to finished products.

We have distributors in Southeast Asia, including Malaysia and Thailand. Thailand, in particular, is a key market due to its large customer base in the automotive industry.”

Yong Jyu Sin Plastic Co., Ltd., founded in 2013, is committed to environmental protection and social responsibility with Mr. Huang Chung Min, Vice President, one of the company’s key Executives being a leader. Under his leadership, Yong Jyu Sin Plastic Co., Ltd., is the first company ever to apply environmental protection experience to its manufacturing processes and development of its responsibility on the aspect of the waste management classification and procedural standards while promoting environmental awareness and operational excellence continuously. Because our main business is plastic and metal waste recycling technology, we therefore produce high-quality recycled plastic pellets, including Crushed Materials, Beads, and Functional Plastic Grades. Our recycled plastic pellets are certified and recognized in many countries worldwide, with Southeast Asia being one of our key target markets.We have still continued to carry on our work diligently to attain our goal by believing that “Waste is a resource simply discarded at wrong place.” We strictly adhere to the principle of plastic recycling and waste reductions to give new value to recycled plastics. With a foundation in Taiwan, we are actively expanding our business globally and fully hope that our global clients will understand the value of recycled plastics and metals better.

YU PO Chemical Co., Ltd. established in Taiwan in 1983, is focused on the formulation and processing of epoxy resins. In 2023, it became part of the NAN PAO RESINS GROUP. Ms. Pink Chen, Assistant Technical Manager, gave her account about the company: Our products can be combined with carbon fiber, fiberglass, and other bio-based fibers. They can be applied in various processes such as composite manufacturing, infusion, pultrusion, filament winding, and mold forming. Our materials are known for their versatility and high performance, including high TG values, excellent strength and toughness, rapid and low-temperature curing, flame resistance, transparency, and weatherability. These resins are widely used such as in wind energy, aviation and aerospace, automotive, rail transportation, electronics, and sporting equipment.

“Recently, we’ve expanded market to Thailand and are now collaborating with composite manufacturers and molding plants in Thailand. We offer technical services to help clients analyze materials and solve production issues.”

Our production philosophy focuses on delivering value-added, environmentally conscious products, services, and solutions aimed at becoming a global company committed to sustainability, environmental stewardship, and social value.”

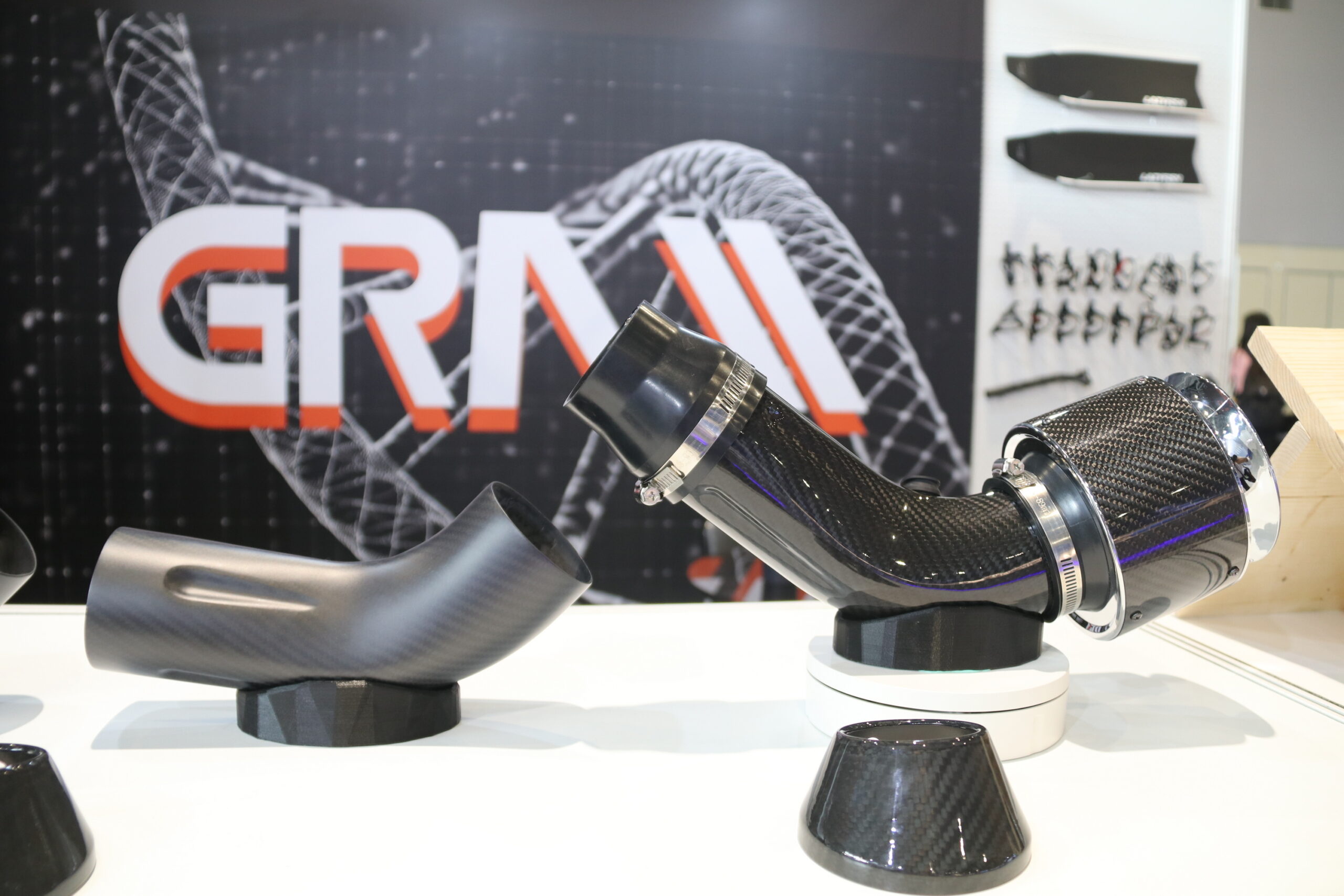

GR Applied Materials Co., Ltd., a carbon fiber product manufacturer from Taiwan with over 30 years of industrial experience, has the potential to offer exceptional ODM/OEM services for customized carbon products. In this regard, Mr. Zack Yang, Special Assistant to the General Manager, noted: Our Taiwan-based manufacturing facilities produce carbon fiber products recognized across various industries because our products are adopted for use in the productions of a variety forms of products such as Diving Gears, Automotive Parts, Bicycle Parts, UAV Parts, including customer-specific applications. We also provide comprehensive after-sales support.

“Thailand is one of the fastest-growing countries in ASEAN, especially, in the automotive industry, which demands lightweight materials. We see strong potential to enter Thailand’s carbon fiber market, given our high-quality products. We are committed to consistent customer support, with a dedicated team offering design and product development consulting services particularly for OEMs that require carbon fiber for their production needs.”